AD*STAR® bag advantages

DURABLE AND STRONG

AD*STAR® bags withstand very harsh handling conditions and are virtually indestructible during filling, automatic feeding, loading and transportation. At all stages of the product life from producer to consumer, filled bags can be subjected to many transfers, throws, falls from different heights, and often just carelessness of people. But it will not lead to fatal destruction of the cover and complete loss of the content.

STABLE AND RESISTANT

Due to the complete coating of the polypropylene fabric maximum protection of the cargo from moisture is provided, moreover, it protects the environment from its impact: content which is not always neutral. Besides, the bags can be perforated for air penetration and, conversely, to achieve maximum tightness a valve can be welded at the bag after its packing.

EASY-TO-USE

AD*STAR ® polypropylene valve bag is a rectangular block. It is easy to operate the bag both manually and with the help of mechanisms (vacuum manipulators). Due to the special surface treatment of the fabric, the bags do not slip and form a stable structure of the correct shape when packed.

ENVIRONMENT-FRIENDLY

Polypropylene is a recyclable material. The range of products produced with the addition of recycled polypropylene or made entirely of it is expanding every day. The number of technologies is growing and the range of application of such products is already incredibly wide from construction and landscaping to automotive industry. As a material polypropylene is not toxic and poses no hazard to soil, water or air.

COST-EFFECTIVE

Savings start as early as the product is being packed. Firstly, there is less rejection due to tare fault. Secondly, the entire filling and packing process can be automated to a greater extent and at a lower cost. As a consequence, the number of operators is reduced and wage costs are lower in this division.

Savings in warehouse space, mechanization of loading and unloading operations, reduction of losses during transportation and storage – all these factors have a tangible effect on the amount of money saved. Definitely, the larger the manufacturer is, the greater the benefits can be achieved in packaging from the use of AD*STAR® bags.

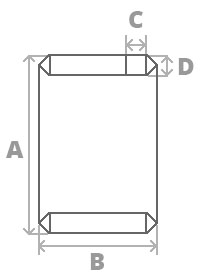

Bag length, cm 45 – 91

Bag width (width of coated sleeve fabric), cm 35 – 60

Valve length, cm 11 – 15

Bottom width, cm 8 – 18

А – bag length;

B – bag width;

C – valve length;

D – bottom width